+86-18052658805 | 18052655285

At present, the development of Applied Optics is rapid, large-scale, continuous coating production has been widely used, the development of digital optics, display and so on has a large demand for optical films. Especially for all kinds of filters used in visible band, the global demand for filters is far more than 1 billion in a year. Moreover, with the continuous development of large-scale, the cost of thin films has been paid more and more attention. There are two main factors restricting the cost of optical thin film components: coating materials and film yield. Therefore, it is necessary to develop the preparation technology of low-cost coating materials and improve the stability of the coating process to improve the yield.

The optical thin film system realizes the special optical function by alternately depositing high and low refractive index thin films. At present, silicon dioxide (SiO2) is the representative of low refractive index materials, which has stable properties and limited space for cost reduction. However, the price of high refractive index materials is often high, and the properties of some coating materials are not very stable. The research shows that the addition of some rare earth compounds, such as lanthanum titanate (LaTiO3), can significantly improve the unstable properties. On this basis, high stable high refractive index materials are obtained.

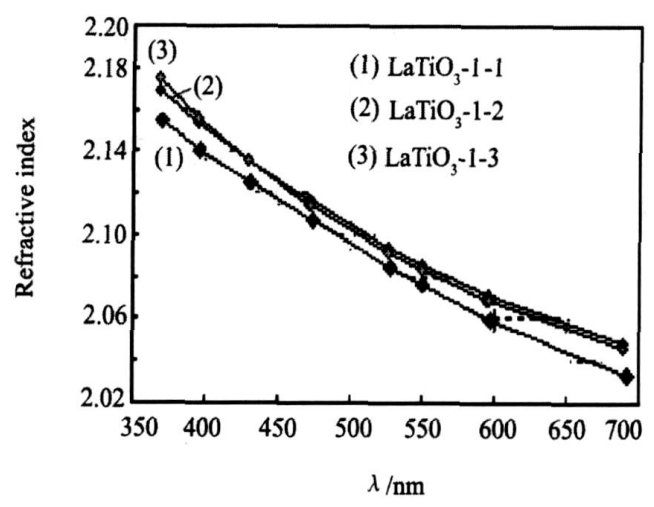

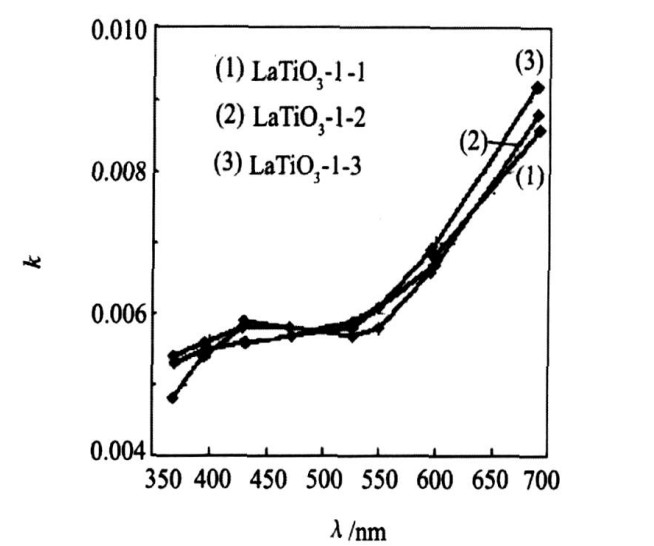

Through the preparation of lanthanum titanate (LaTiO3) monolayer and multilayer antireflection film AR, understanding the properties of lanthanum titanate thin films. The refractive index and extinction coefficient of the prepared monolayer film in the whole visible band are measured by spectrophotometer for three times, as shown in P1 and P2.

P1: Refractive index of single layer film

It can be seen from P1 that the refractive index of lanthanum titanate (LaTiO3) material is between 2.03 and 2.18 in the whole visible band, the dispersion is good, and the average deviation of the refractive index of three times is 0.14, and the repeatability is good. It can be seen from P2 that in the whole visible band, the extinction coefficient K value is between 0.0005 and 0.0009, and the K value of the third film is relatively stable.

P2: Extinction coefficient of monolayer film

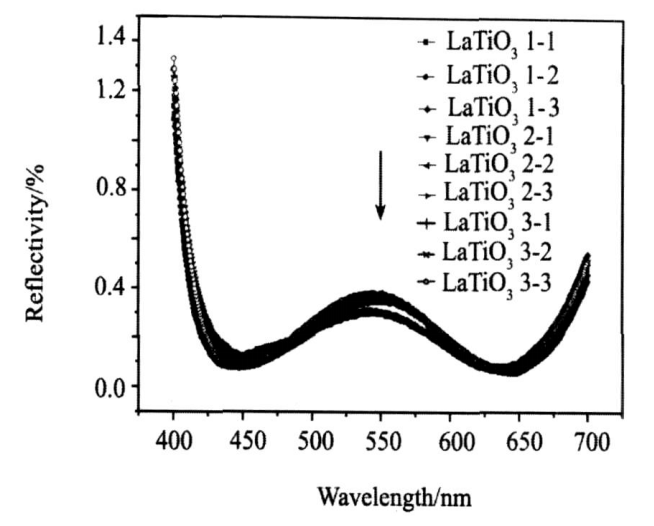

The preparation of multilayer antireflection film AR is to prepare AR film with silicon dioxide (SiO2) as low refractive index material. The substrate is K9 glass, which is repeatedly plated three times, each time with three pieces, respectively placed in the upper, middle and lower positions of the planetary cover to analyze the uniformity of the film. The reflectivity of the film in the whole visible band is measured by spectrophotometer, as shown in P3.

P3: The change of reflectivity of multilayer AR film with wavelength

It can be seen from P3 that the reflectivity is the lowest at the wavelengths of 430 and 650nm, about 0.1%. At the wavelengths of 550nm, the refractive index difference of the nine substrate films with reflectivity is about 0.07%, showing good stability and repeatability.

Lanthanum titanate (LaTiO3) optical coating materials show good performance and stability in refractive index, extinction coefficient and multilayer AR films, and have a good prospect of application. ATS is a professional manufacturer of vacuum coating materials. Its lanthanum titanate coating materials are recognized by customers. Welcome to contact us!

Copyright © 2017 泰州市爱特斯光学材料有限公司 . All rights reserved