+86-18052658805 | 18052655285

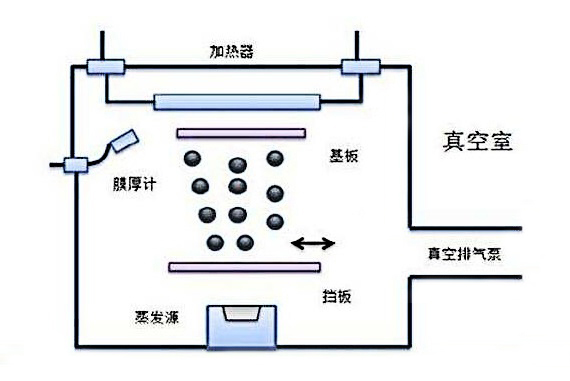

Generally, the material and shape of the evaporation source shall be considered, the requirements for the material of the evaporation source are:

(1)High melting point. Because the evaporation temperature of the evaporation material (the temperature with the equilibrium vapor pressure of 1.3pa) is mostly between 1000 ~ 2000 ℃, the melting point of the evaporation source material should be higher than this temperature.

(2) Balance steam pressure is low. This is mainly to prevent or reduce the impurities of the evaporation source material from entering the evaporation coating layer with the evaporation of the evaporation material at high temperature. Only when the equilibrium air pressure of the source material is low enough, can the minimum self evaporation be ensured during evaporation, which will not affect the vacuum degree of the system and contaminate the film layer. In order to make the amount of evaporation of the source material very small, when selecting the evaporation temperature and the source material, the evaporation temperature of the material should be lower than that of the source material. When the equilibrium pressure is 1.3 × 10-6pa, the temperature corresponding to 1.3 × 10-3pa can be used to prepare high quality films.

(3)The chemical property is stable and should not react with evaporation material at high temperature. Under high temperature, some materials of evaporation source will react and diffuse with evaporation materials to form compounds and alloys. In particular, it is easy to burn off the steam source of low eutectic alloy. For example, at high temperature, tantalum and gold will form alloy, and aluminum, iron, nickel, cobalt will also form alloy with tungsten, molybdenum, tantalum and other steam source materials. Tungsten can also react with water or oxygen to form volatile oxides such as Wo, WO2 or WO3; molybdenum can also react with water or oxygen to form volatile MoO3. Therefore, the material that will not react with the coating material or form alloy should be selected as the evaporation source material of the material.

As the source of evaporation, the material must have the properties of high melting point, low volatilization and low brittleness after high temperature cooling. The commonly used linear evaporation source should be able to wet with the evaporated metal, and the melting point is far higher than the evaporation temperature of the metal to be plated, so it does not react with the metal to be plated to form alloy.

Copyright © 2017 泰州市爱特斯光学材料有限公司 . All rights reserved