+86-18052658805 | 18052655285

The vacuum plating tungsten wire is processed by heating with natural gas, which can reduce the trauma and has an ultra long service life. The surface is ultrasonic cleaned and electroplated polished, which is brighter and cleaner. It is the best product for coating high-grade products. Because of its strong corrosion resistance, high temperature performance and stability, and long service life, it is widely used in mirror industry, picture tube industry, vacuum coating of film technology, metal evaporation and other fields.

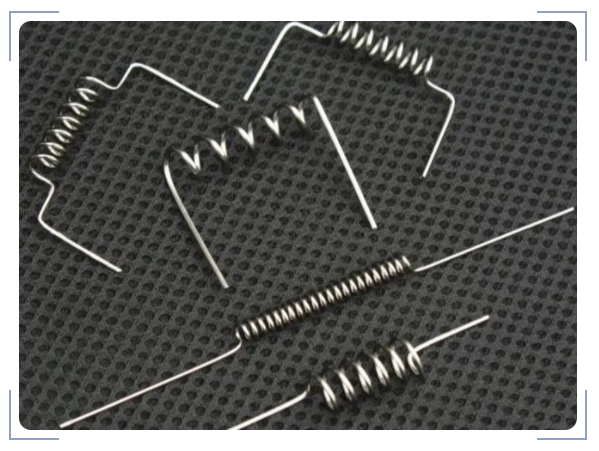

The types of vacuum plating tungsten wire mainly include gate type tungsten wire, zigzag type tungsten wire, peak type tungsten wire, wave type tungsten wire, cone type / funnel type tungsten wire. The coated tungsten wire is mainly used in the cosmetics industry, electronic products series, automobile accessories, vacuum eyeglasses, heels, small commodities, sun hats, glasses, helmets, collection accessories and other vacuum coating.

The fine tungsten wire on the surface of the gate type tungsten wire has the function of adsorbing liquid aluminum, which makes the aluminum diffused evenly, does not drop, evaporates quickly and does not form aluminum ball in the vacuum melting state. The gap between the tungsten wires of the door-shaped tungsten wires made of multiple strands is large, which can easily absorb the liquid aluminum, do not explode the aluminum, do not drop the aluminum, and volatilize easily. Tungsten wire with one shape has good properties of high temperature resistance and sagging resistance. It is mainly used for heating silica or powder particles in evaporation metal box. The production process is not electrified and there is no electric shock. It is heated by natural gas. It has good elasticity and is not easy to break. The latest ultrasonic cleaning process is introduced. The surface treatment is cleaner, brighter and smoother, which can ensure that the plated workpiece is spotless. The peak type tungsten wire is not electrified in the production process, and there is no electric shock on the surface, which can greatly prolong the service life of tungsten wire. The suitable voltage of the corrugated tungsten wire is 24V, the current of the lamp is 20A, and the suitable pipe diameter is 20 mm. It is mainly used for the heating element of vacuum plating. The taper type tungsten wire, also known as funnel type tungsten wire, has a circular cross-section and is widely used in evaporation coating process.

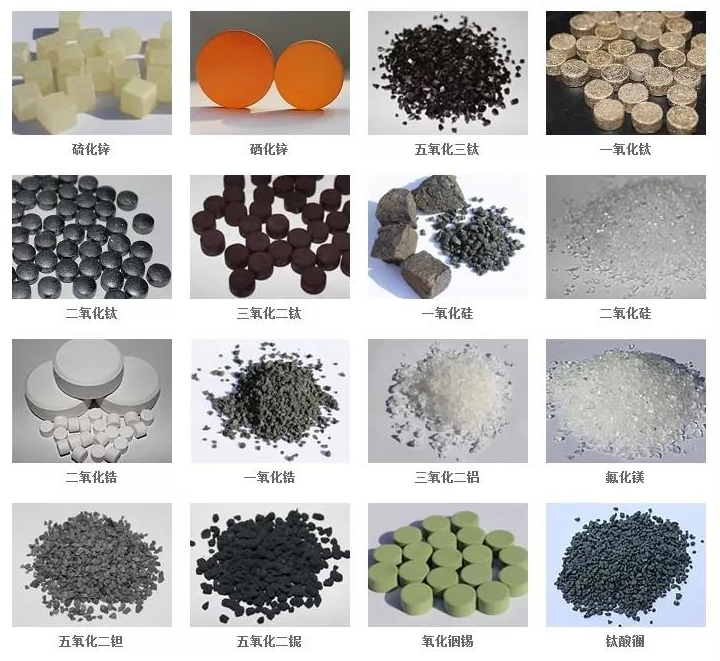

ATS is a professional manufacturer of vacuum coating materials. In order to provide one-stop procurement service for customers in cooperation, ATS has been acting as an agent for other optical materials and coating accessories since 2015. Tungsten wire is one of the coating accessories. If you need coating materials and coating accessories, please call us at any time!

Copyright © 2017 泰州市爱特斯光学材料有限公司 . All rights reserved